What is Container Loading Supervision?

Container Loading Supervision (CLS), also known as Container Loading Inspection (CLI) or Container Loading Check (CLC), is a quality control inspection that ensures that goods are handled correctly during container packing. Container loading inspection service is the final step in your product quality control system before your goods leave your supplier’s factory in Asia and are shipped overseas. Therefore, the China Look Group team strongly recommends conducting the CLS service to avoid any unnecessary surprises when your goods arrive at their final destination.

Container Loading Supervision is a vital part of ensuring that your cargo is loaded and shipped in a satisfactory condition. CLS Inspection services provides comprehensive inspection report detailing the cargo loading process and verifying that your goods are being loaded according to your specifications. With Container Loading Supervision, you can rest assured that your cargo is in good hands and that it will arrive at its destination in a satisfactory condition.

Where is Container Loading Supervision in China Conducted?

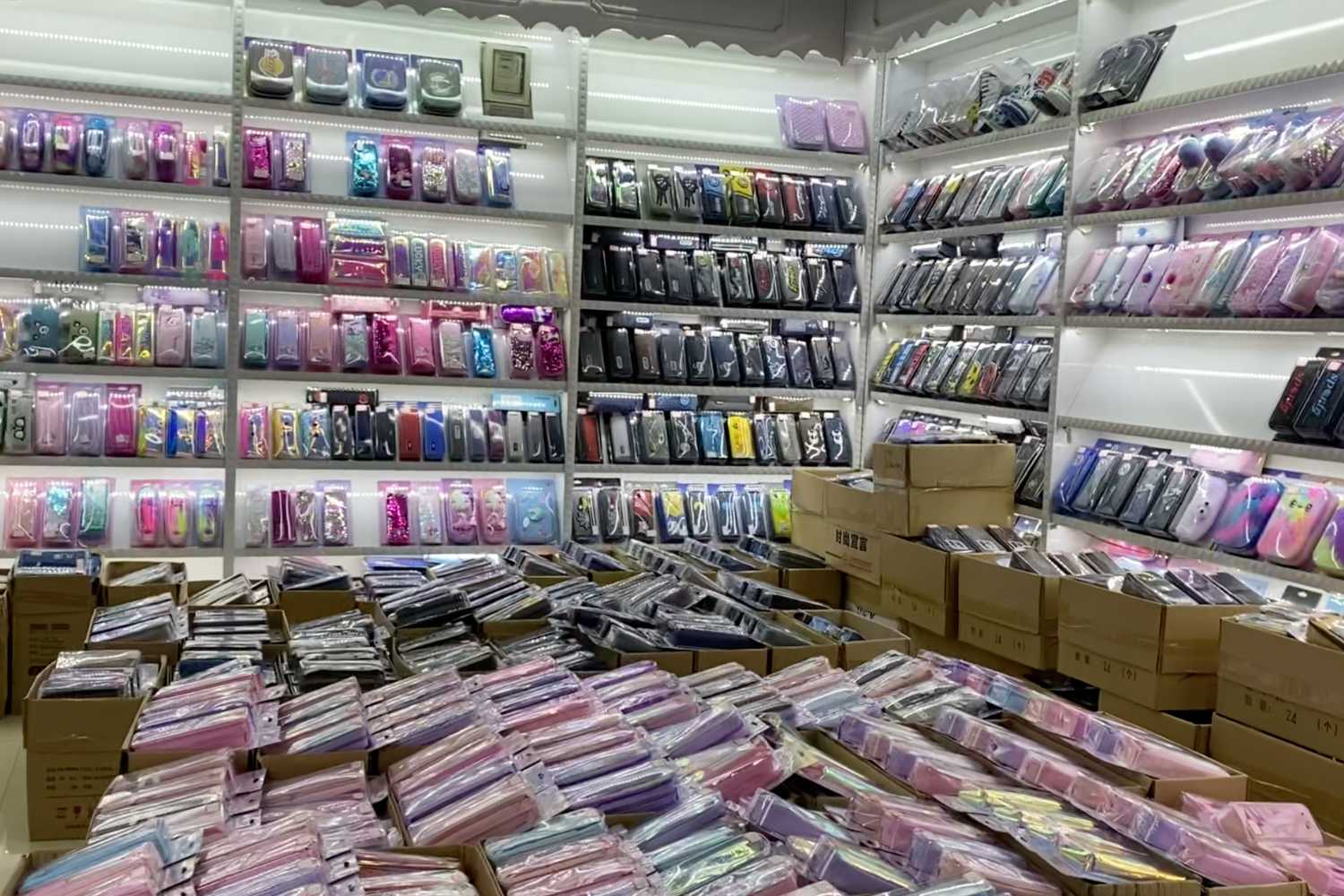

China Container Loading Supervision services are conducted at the supplier’s factory warehouse, the forwarder’s warehouse, or any other facility where your final goods are stored before being offloaded for international forwarding.

Container Loading Inspection is conducted when 100% of your order has been packed for export and is ready for container ship loading.

Container inspection checklist before loading:

We take container loading seriously, and that’s why we conduct a thorough pre-loading container inspection to ensure that the container is loaded correctly. Our inspection includes checking the container state, shipping mark, documentation, and loading list, as well as the condition of cartons, pallets, and pallet packing.

Container inspection

Shipping marks

Carton and packaging condition

Random quality check

Pallet and master box count

Labelling

Loading process

Sealing of the container

Note.

Importers should note that CLC verifies product type, quantity and packing details but not product quality. Pre-shipment inspection is recommended before CLC.

Container loading inspection is performed only for full container loads (FLC). Look Inspection generally performs 1-2 FLC full container load supervisions per day.

Note: It is important to communicate any specific container loading inspection report requirements with ChinaLookGroup beforehand to ensure that the report meets your needs and expectations.